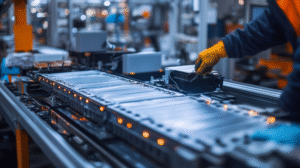

Manufacturers operate in a world where precision defines success. Every process, from molding plastics to finishing automotive paint, depends on strict environmental control. While many facilities monitor temperature, airflow, and cleanliness, they often overlook one factor that silently shapes outcomes: humidity.

When humidity drops too low, static electricity builds, attracting dust and risking electrostatic discharge (ESD). Adhesives dry too quickly, wood panels crack, and baked goods lose freshness. Too much humidity brings its own challenges: condensation, microbial growth, and packaging failures. These shifts compromise product quality, worker safety, and process efficiency.

Manufacturers who install reliable humidification systems gain more than environmental balance. They protect materials, improve yields, and create safer working conditions. Modern high-pressure systems now allow precise, energy-efficient humidity management that adapts instantly to production demands.

This guide explores how manufacturing humidification strengthens outcomes across industries, including plastics, automotive, woodworking, and food processing. You’ll see why leading facilities treat humidity control as a strategic advantage, not a secondary concern.

Why Manufacturers Rely on Humidity Control

Manufacturers don’t leave quality to chance. Every input counts—and humidity is no exception. By actively controlling humidity, facilities eliminate variables that cause waste, defects, and downtime.

- Static Control and ESD Protection

Dry conditions encourage static electricity in manufacturing environments. That static attracts dust, interferes with precision components, and can spark ESD events that damage electronics and halt production. Proper humidity supports natural dissipation and contributes to effective ESD prevention. - Product Quality and Dimensional Stability

Materials respond directly to moisture in the air. Wood shrinks, plastics distort, and adhesives lose their bond when humidity drifts. Balanced humidity locks in consistency. - Adhesives, Paints, and Coatings

Finishes require exact curing conditions. Stable humidity prevents cracking, peeling, and weak adhesion. Facilities that control humidity deliver smoother, stronger finishes. - Worker Comfort and Safety

Low humidity means dusty air and dry skin. High humidity means slippery surfaces and condensation risks. Balanced levels reduce airborne dust, improve comfort, and keep the environment safe.

Manufacturing humidification eliminates these risks and provides predictable conditions. By doing so, it transforms plant performance from reactive troubleshooting to proactive consistency.

Plastics Manufacturing Humidification

Manufacturers who introduce plastics manufacturing humidity control keep these problems in check. Proper humidity dissipates static naturally, ensuring clean surfaces and safe operations while supporting static charge reduction in plastics production environments

- Injection Molding: Balanced humidity improves resin flow and ensures smooth surface finishes.

- Extrusion: Stable conditions maintain dimensional accuracy across long runs.

- Packaging: Static reduction prevents film clinging and packaging jams.

For electronics-grade plastics, electrostatic discharge protection in plastics manufacturing is critical. A single ESD event can ruin sensitive components or wipe out entire batches. By maintaining optimal humidity, plastics facilities reduce scrap, protect equipment, and boost yields.

Automotive Manufacturing Humidification

Few industries rely on finishes as much as automotive. Paint booths demand precise automotive paint humidity control to avoid defects like cracking, blistering, or uneven curing. Low humidity also increases airborne dust, which sticks to surfaces and ruins finishes.

Beyond painting, automotive assembly humidity management is essential for electronics. Sensitive circuit boards face constant ESD threats in dry environments. With proper humidity, static dissipates safely, providing effective ESD prevention in automotive production and protecting both products and workers.

Facilities also benefit operationally. Stable humidity levels reduce dust along assembly lines, improving air quality and minimizing maintenance downtime. Workers stay more comfortable, which lowers fatigue and improves precision during repetitive tasks.

Automotive manufacturers who implement humidity control consistently report lower rework rates, smoother finishes, and improved worker safety. In an industry where margins depend on efficiency, these gains translate directly into competitive advantage.

Woodworking Manufacturing Humidification

Wood reacts to humidity more than almost any other material. In dry environments, boards shrink, crack, or warp. In humid conditions, they swell or distort. These shifts cause inconsistent cuts, weak joints, and costly rework.

Woodworking manufacturing humidity control locks in material stability. By maintaining consistent moisture levels, facilities reduce waste and protect dimensional accuracy.

Strong bonding depends on the relationship between adhesives and humidity in woodworking. Glues cure better in stable air, creating durable joints that last. The same holds true for coatings. Paint and finish humidity in woodworking directly affect how evenly stains spread, how well paints cure, and how long finishes resist peeling or flaking.

Furniture, cabinetry, and flooring manufacturers especially depend on these controls. A warped panel or uneven finish not only wastes material but also undermines customer trust. By managing humidity, woodworking facilities deliver consistent quality and extend the life of every finished piece.

Food Processing and Packaging Humidification

In food manufacturing, humidity control directly protects both products and packaging. Dry air dries out baked goods, brittle packaging materials, and powdered foods. Excess moisture creates condensation, microbial growth, and contamination risks.

Facilities that use food processing humidity control preserve product freshness and extend shelf life. Humidity in food manufacturing also prevents baked goods from becoming stale and powders from clumping. For fresh produce, it keeps moisture content stable.

Packaging also benefits from dedicated packaging humidity management. Adhesive labels stick reliably, seals stay intact, and films resist static cling. By controlling humidity, facilities ensure packaging remains strong from the production line to the consumer’s hand.

Dust also decreases in properly humidified plants. That improves hygiene, protects equipment, and creates safer conditions for workers.

With humidity management, food processors deliver fresher products, extend shelf life, and ensure consistent packaging quality.

Also read: Food Processing and Packaging Humidity Control: Ensuring Product Quality, Safety, and Efficiency

High-Pressure Humidification Systems in Manufacturing

Traditional humidifiers often lack the precision, scalability, and efficiency that manufacturers require. High-pressure humidification systems solve these challenges by delivering accuracy, energy savings, and broad coverage.

- Precise Delivery: Systems adjust instantly, keeping humidity levels steady even during production swings.

- Energy Efficiency: Variable-frequency drives (VFDs) cut energy use while maximizing output.

- Scalable Coverage: From small process rooms to large warehouses, systems deliver consistent results.

- Seamless Integration: Automated humidity control systems connect with existing building management platforms, enabling full facility-wide regulation.

With high-pressure humidification, manufacturers control humidity proactively, reducing waste, improving uptime, and protecting sensitive processes. These systems turn humidity from a problem into a predictable, optimized variable.

Best Practices for Manufacturing Humidity Management

To maximize performance, manufacturers treat humidity as part of their quality control strategy. Successful plants:

- Monitor Continuously: They use advanced sensors and automated systems to track humidity in real time.

- Customize by Industry: They adapt humidity levels to specific processes—plastics, automotive, woodworking, or food each require different ranges.

- Maintain Equipment: They schedule regular service to ensure pumps, nozzles, and sensors operate flawlessly.

- Integrate Systems: They connect humidification control to building management systems, ensuring seamless environmental management.

By following these best practices, facilities stabilize operations, extend equipment life, and reduce downtime. Humidity management becomes a driver of consistency, not a variable to fight against.

The Strategic Value of Manufacturing Humidification

Humidity quietly shapes the success of every manufacturing process. Plastics attract dust and static without it. Automotive paint fails to cure properly. Wood cracks and adhesives weaken. Food loses freshness and packaging breaks down.

Manufacturers who invest in manufacturing humidification gain control over these risks. They improve product quality, protect equipment, and safeguard workers. High-pressure industrial humidification systems provide the precision, efficiency, and scalability modern facilities need.

In an industry where margins are tight and reputations hinge on quality, humidity control in manufacturing becomes more than an environmental adjustment. It becomes a strategic advantage that protects products, boosts efficiency, and keeps operations running at their peak.