Condenser Coil & Process Cooling Systems

In high heat, air-cooled condensers lose much of their efficiency and your equipment must work harder to maintain desired temperatures. The MicroCool system for cooling condenser coils puts fog nozzles in front of the coil. Flash evaporation of the water in the air extracts heat and lowers temperature by up to 30°F (18°C). Industries across the globe turn to us for the advanced process cooling solutions they need to maximize the efficiency, reliability and long life of their manufacturing processes.

The new wave in industrial process cooling has arrived.

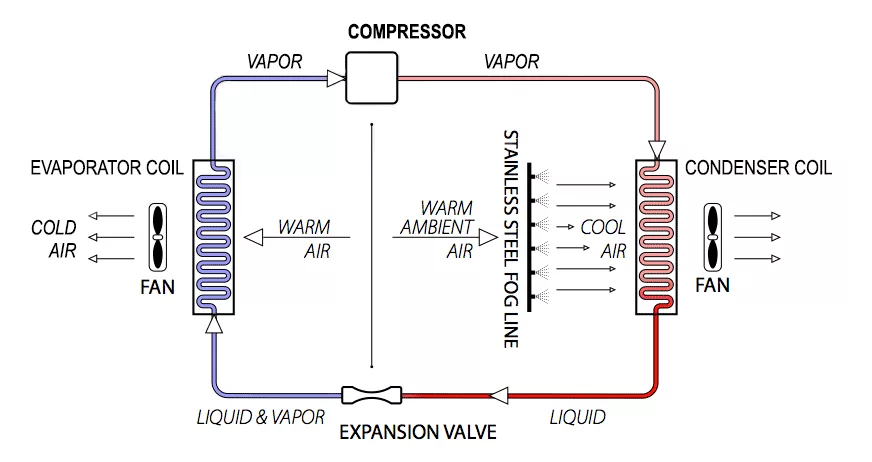

How a MicroCool Fogging System for Air Cooled Condensers Works

Standard sizes vary from 2-15 US gpm (0.5-55 m3/h) with controls. Larger and smaller sizes are available on request.

Special units are available for less frequent usage (peak demand control).

Powerful Results

The “flash evaporation” of water has long been known to drastically reduce air temperatures in hot climates. MicroCool’s water condenser coil process cooling systems meld this age-old principle with the latest technology, achieving dramatic benefits.

- Higher cooling efficiency — The cooling potential of one MicroCool nozzle is the equivalent of about one ton of air conditioning!

- Reduced costs — Reduced energy consumption and equipment maintenance.

- You’re in control— You’re in control— Your systems only run when they are needed, at temperature peaks and when conditions are right for optimal atomization.

- Water savings — The MicroCool condenser coil cooling system uses significantly less water compared to spray and pad systems, and a fraction of the water used for cooling towers.

Cooling Natural Gas Pipeline Stations – A Case Study

MicroCool’s evaporative pre-cooling system works on the immediate surrounding air to maximize cooling systems that exceed their capacities in hot weather and become less efficient.

High pressure fog enables compressors to maintain production levels and stay online during hot weather conditions.

Conserving Water

A MicroCool adiabatic process cooling system uses significantly less water than spray and pad systems – and a fraction of the water consumed by cooling towers. In addition to saving a precious resource, you save bottom-line dollars.

Temperature and relative humidity sensors help ensure that process cooling applications run only when they’re most effective. Industrial grade controls help determine the operational effectiveness of the cooling system depending on varying climate conditions.

How MicroCool Does It Better

Energy-saving technology. Fog cooling lowers the ambient temperature of the air entering the condenser which reduces the head pressure. By preventing overloads and keeping condensers running during peak temperatures, processes and computers stay cool. By reducing downtime and excessive usage during high-rate periods, operations can reduce operational costs and increase performance. By using the data provided by MicroCool, you can calculate your ROI and learn how lowering inlet air temperatures will increase efficiency, reduce your operating costs and prevent costly downtime.

Additional MicroCool system technology enhancements include:

- UV filters — Eliminate up to 99% of waterborne bacteria

- Nozzles placed in front of the coils — Increases efficiency by cooling the air moving over the coil, reducing energy consumption and costly maintenance

- Water-saving design — Each nozzle uses less than 1.5 USGPH (6LPH)

- Continuous control — Your condenser mist cooling systems operate only when they are the most effective, never wasting water by running outside of their high-efficiency zone.

Low Cost, Long Life, High Performance

Reduced energy costs

Designed to conserve electricity, A MicroCool system not only reduces power consumption to stay in lower tariff zones, but you’ll also use 60% less water compared to utilizing sprinklers and hoses for immediate cooling of condenser coils during periods of high demand.

Extended equipment life

Don’t replace – refresh! MicroCool’s pre-cooling air conditioning equipment is often used to increase the performance of older, “tired” condensers—an alternative to installing replacement or extra cooling units. Cooler running means less strain, better performance, reduced maintenance and repair costs, and longer life, with fewer or zero “high head” incidents.

Lean and green

MicroCool’s condenser mist cooling systems use the latest control technology to optimize energy regain and improve cooling. Your systems won’t waste water by running outside of their high-efficiency zone. Furthermore, environmental sensors maintain constant monitoring of ambient conditions, promptly triggering additional cooling when required to ensure peace of mind for equipment operators.

Applications

MicroCool’s water condenser coil cooling systems are the optimal evaporative cooling solution for many different cooling-related processes, including:

- Air-cooled condenser coils for air conditioning units

- Air-cooled refrigeration units and coolers for cold storage

- Air-cooled heat exchangers and LNG applications

- Geothermal cooling processes and air-cooled industrial chillers

- Data storage and Colocation Center Cooling

Back in 1980s, our challenge at MicroCool was to improve the energy efficiency of air-cooled condensers and HVAC units during hot summer months. We resolved the issue by developing condenser coil cooling technology – based on the principles of flash evaporation – to achieve dramatic results in a short time.

The surrounding air temperature plays a big role in the performance of several industrial processes and must be kept within a certain range. Unfortunately, the cooling function in air conditioner units becomes less effective during intense heat waves, compromising the entire system. High-pressure mist cooling is the best method to stabilize the air condensers’ performance.

MicroCool Offers Fog Cooling Solutions

Our approach is to distribute water – in the form of fog containing millions of tiny droplets – into the air which passes through the condenser coil. Once the fog is released into the air, it vaporizes, thereby absorbing surrounding heat energy and reducing the ambient temperature by as much as 20 degrees Fahrenheit. By improving the cooling efficiency of the condensers, warm indoor air becomes easier to manage.

It’s critical that the size of the droplets and quality of water released is well-controlled in order to prevent minerals from building up on the coils because they are usually made of metal and prone to corrosion.

MicroCool’s fog or mist cooling system is very effective in regulating ambient conditions in outdoor air, such as humidity and temperature levels, to achieve significant cost savings. Our adiabatic cooling approach through high-pressure fog optimizes both the evaporator coil and condenser coil cooling systems in industrial environments.

Benefits of MicroCool’s Fogging Systems

The greatest benefit of our misting or fogging systems is reduced operating expenses and lowering energy consumption. This is mostly achieved by lowering the pressure on the compressor head and lowering the compressor’s amperage. As a result, your compressor life will extend and replacement costs go down. In addition, our systems are designed to run only when needed. The 1500 RPM maximum speed also translates into longer equipment life of pump and bearings.

By utilizing a Variable Frequency Drive (VFD), MicroCool’s condenser coil cooling system allows the motor and pump to run only as much as it takes to maintain 1,000 PSI (pounds per square inch) at the nozzles.

Our designers can also provide reverse osmosis systems to remove problematic minerals from your water. Using this type of water reduces the fog nozzle maintenance and keeps the condenser coils pristine in your air conditioners.

Some people think that a fogging mechanism can damage the condenser coils or evaporator coils during heat transfer. Let us put your mind at ease – that’s not true. Choosing the right scale reduction product is important for creating the perfect pre-cooling system for your air conditioner coils. MicroCool systems are designed to run off of RO treated water that will prevent scale build-up on your outdoor unit coils.

Choose MicroCool Condenser Coil Cooling for Dependable Performance

Our fog cooling systems are a great way to eliminate downtime caused by higher ambient temperatures by optimizing the cooling performance of condensers and compressors in large industrial equipment. MicroCool’s high-pressure 10-micron water fog humidification and adiabatic cooling technology serves a wide range of applications, including agriculture (greenhouses), manufacturing and fabrication, digital printing and paper production facilities, clean rooms and laboratories, natural gas pipelines, storage warehouses, and more.

If you’re struggling with compromised performance of aging equipment, especially an air conditioning system or air-cooled refrigeration unit, our state-of-the-art fogging nozzle system can help. To learn more, contact us online or call us at 1-800-322-4364.