Greenhouse Cooling And Humidification Systems

Environmental conditions can be controlled with a MicroCool fog system so that plants produce superior crops and higher yields. Fog systems are used for two distinct applications in horticulture; humidification and cooling. The fog production is the same in both applications but is controlled by different methods.

Control Temperature • Control Humidity • Create Varying Climate Zones

Controlling Conditions in the Greenhouse

Plants normally thrive within a “comfort zone” of humidity and temperature. Stomata on the leaves open and close depending on the ambient conditions and will largely be more active when a plant is in its particular “comfort zone.”

In growing conditions with humidity levels below 40%, plants tend to lose too much water through their leaves (as the air pressure is less than the pressure in the leaf) and cannot receive enough water from the roots. As a result, the plant becomes stressed and its natural defenses come into play which slows (or stops) growth.

Humidification for Greenhouses

On the other hand, where humidity is high (generally over 85%), the pressure differential is so small that little or no transpiration takes place. Without transpiration, there is no movement of nutrients through the plant and the fruit is starved.

— high and low humidity levels cause plant stress —

To solve these problems, environmental conditions can be controlled with MicroCool fog systems so that plant growth is optimized. Depending on your requirements, fog systems can be used for either humidification or cooling or both.

Greenhouse cooling process

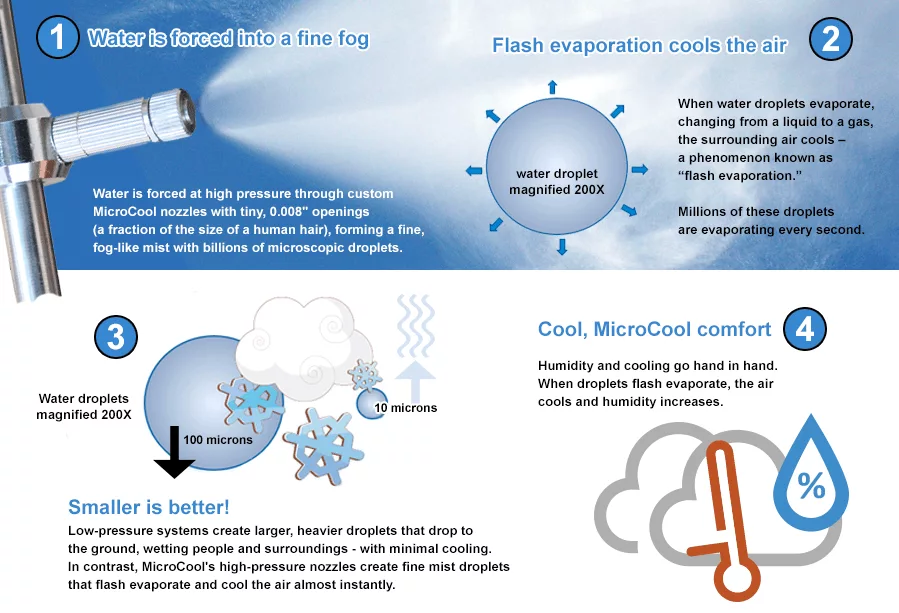

The cooling process is a dynamic event that requires continuous air exchange to facilitate maximum cooling. Once the fog has evaporated and saturation is achieved, no further cooling is possible. However, an influx of warmer, dryer air allows the process to continue.

Flash evaporation also increases humidification as it adds water vapor to the air. Be aware that as humidification levels rise, the rate of “flash evaporation” slows, and accurate control of the process becomes more critical. MicroCool’s control systems can help monitor these situations in order to achieve maximum effectiveness.

How does fog control humidity?

The air in a greenhouse contains a certain amount of moisture that is available to plant material at all times. But, environmental conditions such as heat, poor ventilation and solar effects change the amount of available water moisture.

MicroCool high-pressure fog systems control the amount of moisture and humidity by producing billions of small droplets of water that are evaporated into the air.

How does fog add cooling?

The flash evaporation process is defined as adiabatic cooling and humidification. To illustrate the adiabatic process, imagine the air in a greenhouse as a sponge. When the sponge is dry (low humidity), a large amount of water can be poured into the sponge and can be absorbed before it begins to seep. This large amount of water can be utilized in the adiabatic process for cooling and humidification.

However, if you squeeze the sponge but leave it damp (representing high humidity), much less water can be added to the sponge and therefore less water is “available” for the adiabatic process. This illustrates why adiabatic cooling is much more efficient in arid conditions.

Fog System Design Considerations

From installation to day-to-day operation, to low maintenance and long life, a MicroCool humidification system is the cost-effective choice. With MicroCool, you can have the very latest industrial humidification technology and performance and bottom-line savings.

The design of a high-pressure fogging system is determined by the particular needs of the individual grower. Is the prime requirement for cooling or humidification?

If cooling – what is the desired level and what is the maximum humidity that plants can tolerate? If only humidification is required, other factors need to be considered. Will humidification be required when vents are opened? If so, will a rise in temperature reduce the amount of available water (thus reducing the humidity)?

Fog System Design Considerations

Once the grower’s requirements are known, then atmospheric conditions must be studied. And, although averages are often reported by meteorological offices and stations, these are of little use to a MicroCool designer as extremes can distort an average reading. If in doubt, your specialist can consult ASHRAE charts to determine sample data from your area. This data is then factored into the systems’ cooling potential.

Ventilation

The type of ventilation and positioning of vents and/or fans are important factors in designing and optimizing a fog system. And, any thermal or shade screen installations will affect the air flow. Knowing how the air moves within the greenhouse dictates the positioning and layout of nozzles and pumps.

Sectioning controllers

Sectioning controllers are used to divide the room into different climate zones. Engineers will calculate the fewest number of zones possible to provide an optimal yet cost effective installation.

Ambient temperature

The most important data required is the ambient temperature and humidity when cooling (where humidification is required). One of the biggest mistakes people make in submitting this information is to offer the maximum daytime temperature and the maximum daytime humidity for the period. However, these two comparisons aren’t useful, as both “maximums” never occur at the same time. Recording the temperature and humidity readings on an hourly basis offers a more accurate representation for sizing an appropriate configuration.

Open space above plants

An efficient fog installation also depends on calculating the proper amount of open space above the crop height. Generally a space of approximately 30-36″ (750-1,000mm) is required for successful evaporation. Without sufficient space to “move” and evaporate fog, wetting and dripping could occur.

Humidity at maximum temperature

It’s important to know the humidity level at the maximum temperature. Because as the humidification level rises, the rate of “flash evaporation” slows. This data must be calculated to ensure a sustained flow of fog.

Nozzles

MicroCool will compile all this data and calculate the amount of water (usually expressed as “pounds” or “kg”) required for the desired functionality. Based on years of fog system design experience, he creates a grid or nozzle pattern to deliver optimal fog distribution.

Depending on the number of nozzles required, a high-pressure pump unit is specified and the hydraulic distribution systems are mapped out. Correct pipe sizing and lengths are determined to ensure correct drainage and operation.

System Control is Critical

A well-designed fog system with a non-integrated controller can cause problems. So, scrimping on an inexpensive controller at this stage is a false savings. MicroCool controllers on the other hand provide:

Integration

MicroCool controllers will measure both temperature and humidity with electronic sensors. The sensors integrate the opening of ventilators with fan operation for optimal air exchange and control. More complex computer driven systems are able to predict situations and change the operating frequency of the fog system to accommodate changing environments.

Temperature Control

For cooling, the humidity level is generally the guiding point. The desired temperature is entered into the controller and the maximum humidity level for optimal plant growth is entered. If the system reaches the maximum humidity level, no further cooling will take place since the air has reached saturation.

Ambient Condition Tracking

Although fogging occurs only when the humidity is below the set point, MicroCool systems track changing ambient conditions and make adjustments to provide maximum environmental control.

Humidification Control

Humidification is monitored with the same controller. However, when trying to achieve maximum levels of 85 – 90% humidity (for propagation), care must be taken so that the system does not “overshoot” and saturate the air. Careful design by your planning specialist generally avoids this issue.

Choosing a Fog System for Greenhouse Applications

Difference Between a Fog System and a Misting System

There are significant differences between a fog humidification system and a misting system for greenhouse use. Many manufacturers use these terms interchangeably, which is not accurate. Some may claim that they have a fog system when in reality, they install misting nozzles that deliver a fine mist to your greenhouse plants instead of fog.

We can categorize the differences between both systems under the following:

Particle Size

Particles created by misting nozzles are considerably larger at between 50 and 100 microns. For reference, 50 microns is around 0.002 inches in diameter, and human hair is 0.004 inches in diameter. In contrast, fog particles generally have sizes below 50 microns.

The best fog machines generate water particles with a size of just 8-10 microns in diameter. Lab studies show that MicroCool fog humidification systems generate fog particles that are even smaller than 8-10 microns in size.

Evaporation Rate

Greenhouse misting systems create particles that are larger and heavier. These larger particles take a longer time to evaporate, and many do not evaporate at all. They end up settling on the plant leaves or the soil, making things noticeably wet or moist.

In contrast, the smaller fog particles evaporate almost instantaneously, generating the evaporative cooling effect you want to create consistent conditions. Even the larger particles stay suspended in the air and eventually get vaporized.

Disease Risk

Mist particles tend to settle on the foliage and ground inside the greenhouse environment, as already noted. If not used in moderation, a greenhouse misting system can increase the risk of over saturation and foster the growth of mold/fungi, etc. Such misting systems also increase the risk of plant diseases.

Fog particles don’t increase the risk of either saturation or mold growth. It has the least negative impact on the overall well-being of otherwise healthy plants in a greenhouse environment.

Water Pressure

The pump and misting nozzle inside a misting system requires a water pressure rating of 30 to 60 psi to generate adequate levels of mist. A fog system operates under a much higher-pressure rating. To generate particles smaller than 50 microns in size, a fog system uses between 800 to 1,200 psi.

When to Use Fog Humidifier in a Greenhouse

The primary purpose of a fog system is to reduce ambient temperature and maintain optimal humidity levels inside the greenhouse. The following are a few reasons why you probably require a fog humidifier:

To Grow Tropical/Sub-Tropical Crops

Many exotic vegetables, fruits, and flowers from South America, Asia, Africa, and Europe can be grown in temperate regions in greenhouses. These include orchids, bananas, pineapples, manioc, yams, and so on. However, they usually require very high humidity levels to thrive, which can be achieved efficiently through a fog system (rather than traditional water spigot sprinkler systems and anti-drip devices).

For Cooling/Humidity in Peak Summers

In California and southern parts of the United States, daytime temperatures in summer can reach 86°F or more (an average of 75°F). In greenhouses, this can translate into much higher temperatures in triple digits. To prevent catastrophic loss of crops due to heat stress, fog systems are very useful.

Rapid Cooling During Heatwaves

Unseasonal and extreme weather events have become more and more commonplace with each passing year. Sudden heatwaves can raise the mercury well past 100°F–110°F in many parts of the continental United States. During such heat spikes, fog-based cooling is the best, most cost-effective option to quickly bring temperatures down by 15°F to 25°F or more.

Vapor Pressure Deficit (VPD) vs. Relative Humidity (RH) for Fog Systems

Both VPD and RH are viable ways to measure humidity inside your greenhouse environment. RH has been the metric of choice for traditional growers using greenhouse misting systems, but in recent years VPD has gained a lot of followers.

RH is not directly related to the process of plant transpiration. However, VPD measures the difference between saturation and current humidity in terms of pressure. Since plant transpiration is powered by this pressure, VPD is a much better metric to keep an eye on plant activity, nutrient intake, and plant stress.

High-Quality MicroCool Fog Humidifier Systems

At MicroCool, we have over 40 years of experience in greenhouse misting and fog cooling systems. If you have any questions about our products, reach out to our fog experts online or by calling 1-800-322-4364 today.